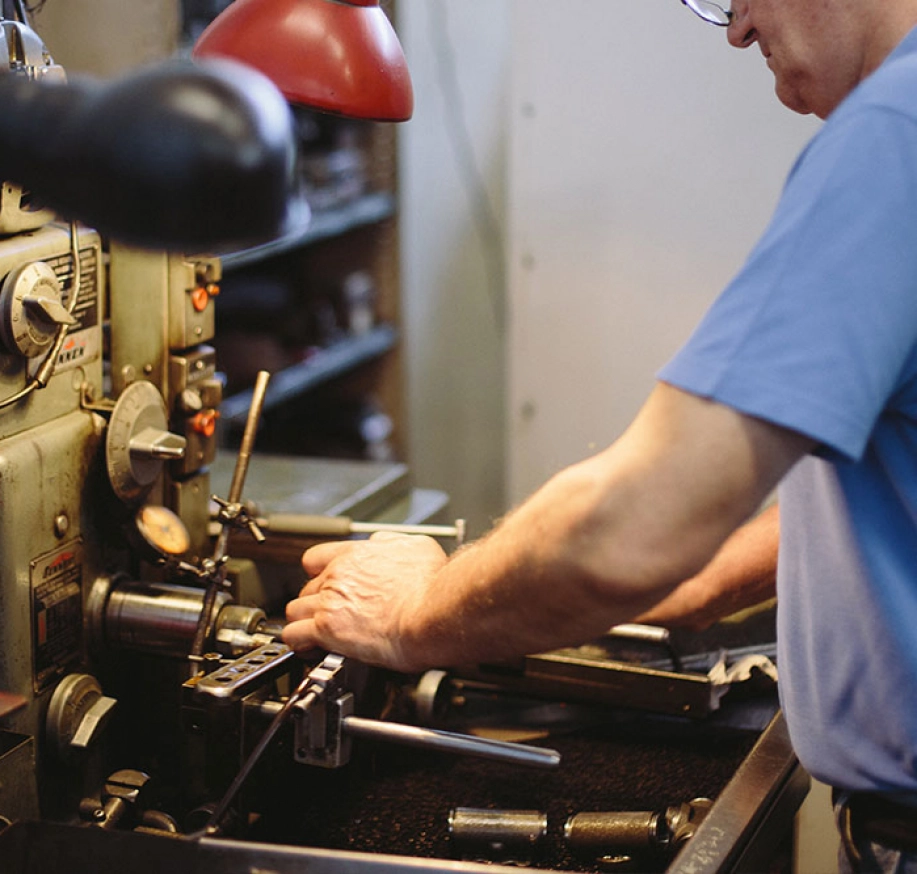

Custom Solutions for Every Need

Our R&D department is able to develop customized solutions for teams and automotive manufacturers. From design to testing, we offer a complete service for one-off projects and specific developments.

Custom Design

Development of custom components according to technical specifications

Advanced Testing

Internal laboratory and track testing for performance validation

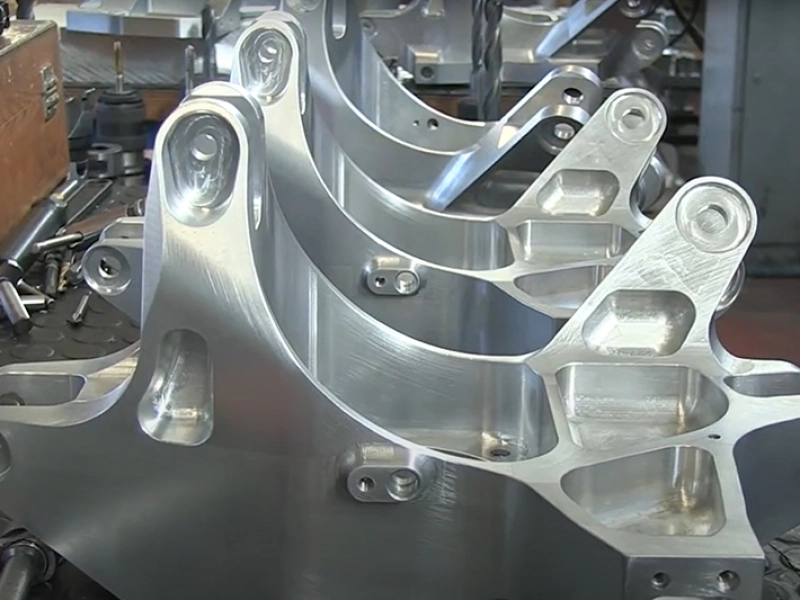

Rapid Prototyping

From design to prototype in record time