Strictly controlled production cycles

Each pad is manufactured under strictly monitored production cycles. Every stage is tested with rigorous controls to ensure the highest standards of quality and reliability.

This approach allows TM to guarantee the highest standards of reliability and performance, crucial for high-level competitions where every detail can make the difference.

Innovative materials for exceptional performance

Crafted with exclusive compounds, TM pads provide durability, thermal stability and consistent braking precision. Even under extreme conditions, they reduce the risk of fading and optimize control.

These advanced materials ensure consistent grip and precise braking, even under the most extreme conditions, reducing the risk of fading and optimizing control on the track.

Special heat treatments for unbeatable performance

With advanced heat treatments, TM pads deliver unprecedented stability and minimize bedding-in time, allowing drivers to achieve ideal behavior from the very first laps.

Drivers can immediately focus on race performance, saving valuable time during the initial phase and ensuring ideal behavior from the first laps.

Complete range for every racing need

The TM100—TM198 range is designed for all racing needs: from maximum grip to extended durability, always ensuring the right balance between performance and reliability.

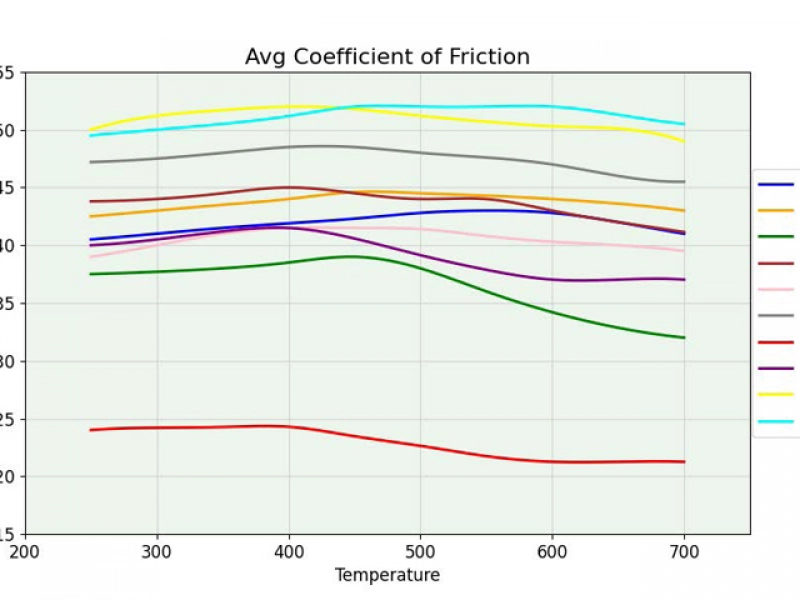

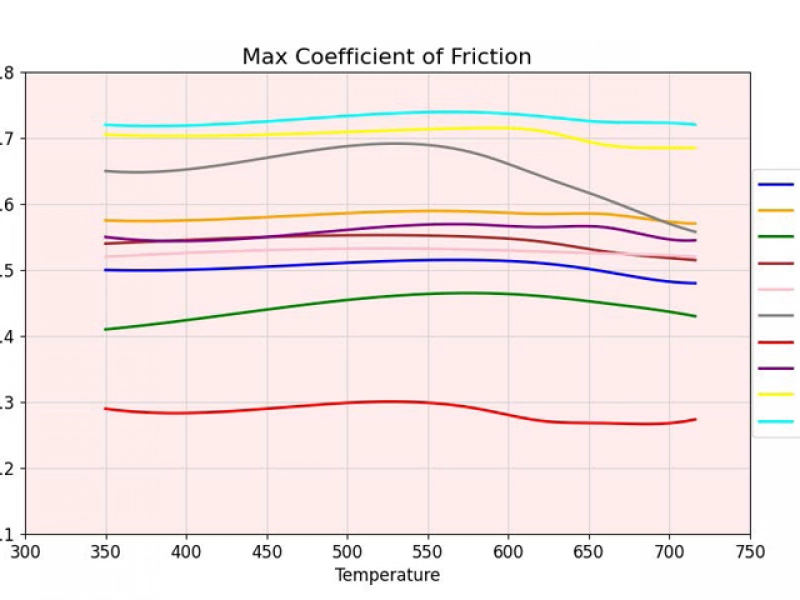

Performance Charts:

The graphs illustrate the variation of the friction coefficient with temperature for our most widely used brake compounds. The data is derived from dyno brake tests simulating real-world braking scenarios, performed under varying G-forces, speeds, brake pressures, and initial disc temperatures.